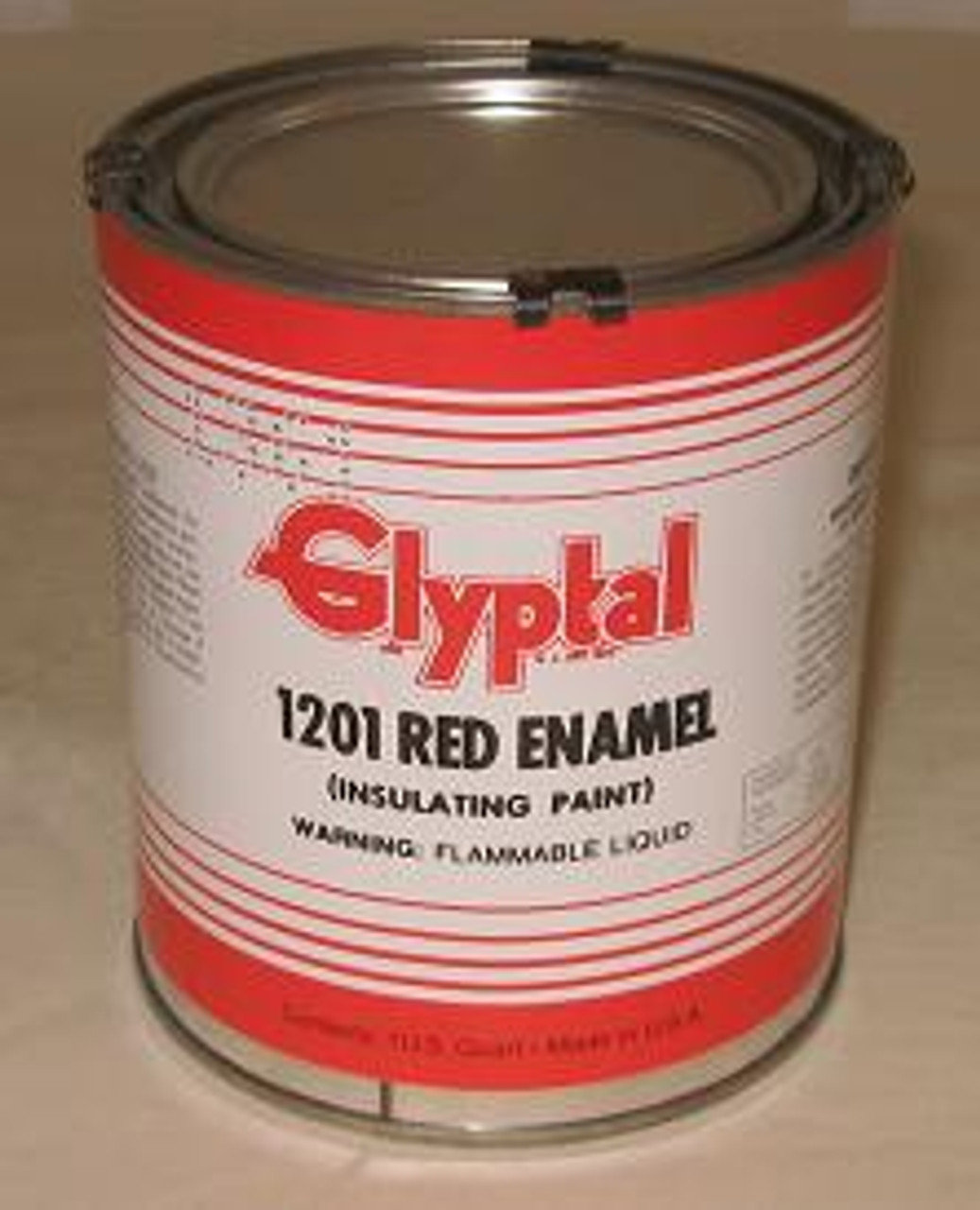

Product Description

The outstanding all-purpose paint

Although 1201 was originally developed as an insulating paint for electrical applications such as the treatment of coils and armatures, its outstanding resistance to corrosion, moisture, oil, acid, heat, dust and salt spray has made it popular throughout industry as a Primer, Sealer, Adhesive and Protective Finish. There are literally hundreds of uses for 1201.

Some of the more typical industry uses include:

- Primer for structural iron and steel . General plant maintenance . Sealer for concrete floors

- Primer and finish for motor, generator, and transformer housings

- Anti-moisture coating on thermostat, water cooler, and truck control parts

- Sealer for pipe and stud threads and vacuum systems

- Anti-corrosion protection for winches ~nd other out- door apparatus

- Electrical insulation for coils and armatures . Adhesive for gaskets

- Coating for interior of hydraulic tanks, and bearing cases.

- Superior performance from a superior paint.

- Exhaustive tests conducted at the Glyptal laboratories confirm consistently favorable customer experience with 1201:

- Meets Requirements of MIL-E-22118

- Flexibility is far superior to competitive red sealers on both backed and air-dried films. 1201 can take rugged impact.

- Water Resistance is excellent.

- Prolonged Aging doesn't crack 1201's film, leaves no place for destructive agents to get in.

- Fast Drying 1201 is tack-free in about thirty minutes at room temperature, can be baked to a beautiful smooth finish.

- Heat Resistance. 1201 has got it, can withstand continuous 135°C temperatures for months.

- Prolonged Heat. After 3700 hours at 35°C, there is no change in dielectric strength.

- Toughness. High-gloss paints have a tender film. 1201 has a low-gloss finish, designed for great resistance to abrasion.

- Adhesion. 1201 hangs on, stays where it's put-on metals, ceramic, porcelain, concrete, fibres, and wood.

- Dielectric Strength is rated at 1500 volts per mil, permits thinner coating than most competitive paints.

- Arc Resistance, even with air-dried films, is 480 seconds.

Safety Information

Hazardous Shipping Info

GHS Info

Product Videos

Product Reviews

Important Information

Additional Equipment May Be Required

For Our Tank Plating Kits:

- Copper Pipe for tank bar

- Copper Wire to hang items

- Small amount of electrical wire to make connections

- DC Power Supply - Included In Some Kits. Check kit contents on web site

- Optional Rinse Tanks (or rinse over the plating tanks with a water bottle)

- Other minor household items may be required, such as gloves, water etc.

For Our Anodizing Kits:

- DC Power Supply (Standard Kit Only)

- 1 Gal Battery Acid

- Dyes (if desired)

- Optional Rinse Tanks (or rinse over the plating tanks with a water bottle)

- Other minor household items may be required, such as gloves, water etc.

Learn More Before Buying

You can purchase our Caswell Plating Manual and learn how to use the kits, before purchasing a kit. Simply Order Here. When you are ready to buy, we will discount the price of the kit.

Already Have Our Plating Manual?

If you are ordering a plating kit that contains our Plating Manual, and you already have our Plating Manual, you can remove it from all kits that contain it and save $30 per kit. Just use Coupon Code NOMANUAL in your Shopping Cart at checkout.