Product Description

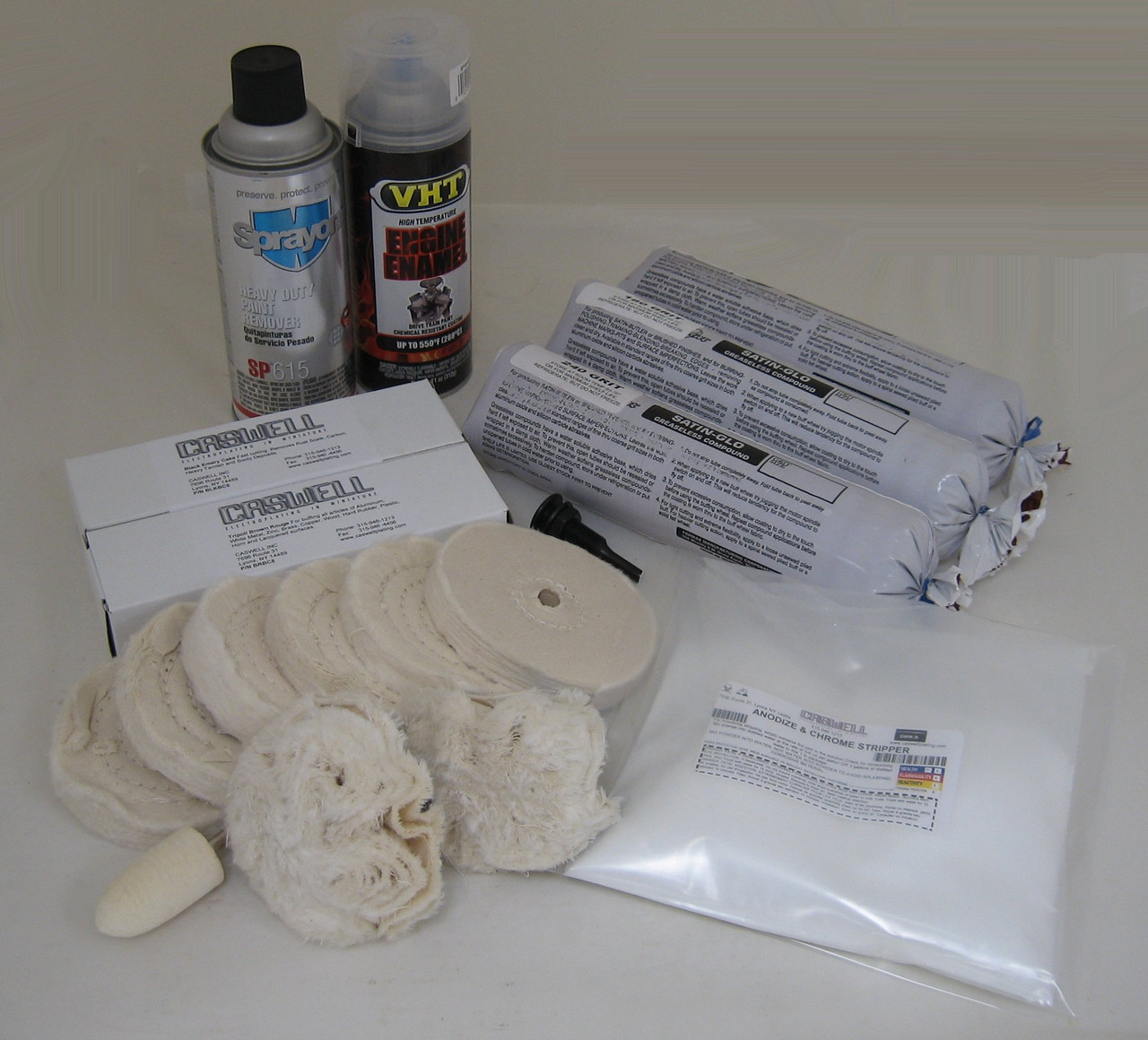

Whether your wheels have been clear coated or anodized, this kit contains the chemicals to remove both types of coating prior to polishing.

| The kit contains:

The work is best done with the tire removed. You need to determine if the wheel has an anodize film or a clearcoat. Apply a paint stripper onto an area on the wheel, and cover with clear plastic such as Gladwrap. Leave for 30 minutes. Remove the plastic and inspect the surface. If there is bubbling and lifting of the film, then it is obviously a clear lacquer, so you can continue stripping the wheel. Covering the stripper with a plastic cling film helps the chemical to react faster. Finish stripping using steel wool to remove all material. To remove anodize film, make up the Anodize Stripper by putting 5 oz of the powder into 1 gal water. Apply liberally with a brush, and allow to soak onto the surface. Rinse off with water after at least 10 minutes. Check for conductivity using a multimeter. If the coating has been removed, then the aluminum surface should be conductive, because anodize is an insulator. Re-apply if the anodize was not removed completely. Using a drill running at approx 2000 rpm, attach a spiral sewn wheel mounted in the Arbor Adapter. Using the 120 grit Greaseless Compound, rev up the wheel and press the bar against it while spinning for about 1 second. Buff the aluminum in one direction, then redo it at 90 degrees. Next, change to a new buffing wheel and use the 180 grit, and repeat the process, buffing in both directions. Next, change to a new buffing wheel and use the 240 grit and repeat the process, buffing in both directions. For difficult areas, use the bullet shaped Felt Bob with all the same Greaseless Compounds. Clean the bob between compounds, by spinning it against a hacksaw blade. Using a new Spiral Sewn Wheel, buff using the Black Buffing compound, then change to the Brown Buffing compound. Buff in both directions. Use the Mushroom and Facer Buffs for difficult access points. Finally, buff the entire wheel using the Brown Buffing Compound on a LOOSE Cotton Wheel. You wheel should now be ready to Clearcoat with a clear lacquer. If you don't want to clear coat the wheel, you should apply a sealer, such as Shine Seal, to prevent oxidization. |

Safety Information

Product Videos

Product Reviews

Important Information

Additional Equipment May Be Required

For Our Tank Plating Kits:

- Copper Pipe for tank bar

- Copper Wire to hang items

- Small amount of electrical wire to make connections

- DC Power Supply - Included In Some Kits. Check kit contents on web site

- Optional Rinse Tanks (or rinse over the plating tanks with a water bottle)

- Other minor household items may be required, such as gloves, water etc.

For Our Anodizing Kits:

- DC Power Supply (Standard Kit Only)

- 1 Gal Battery Acid

- Dyes (if desired)

- Optional Rinse Tanks (or rinse over the plating tanks with a water bottle)

- Other minor household items may be required, such as gloves, water etc.

Learn More Before Buying

You can purchase our Caswell Plating Manual and learn how to use the kits, before purchasing a kit. Simply Order Here. When you are ready to buy, we will discount the price of the kit.

Already Have Our Plating Manual?

If you are ordering a plating kit that contains our Plating Manual, and you already have our Plating Manual, you can remove it from all kits that contain it and save $30 per kit. Just use Coupon Code NOMANUAL in your Shopping Cart at checkout.